Diameter: 25-650mm

Flow rate: 2-9500m3 / h

Head: 10-55m (Step-Simple)

Delin DM (R) series slurry pumps are suitable for delivering middle and low density abrasive slurries in metallurgical, mining, coal and power industries, etc. For example, delivering slurry in mining, metallurgical, power plant, steel mill and chemical industries, etc. 7. The pump Should rotate clockwise viewing from driving end.

Hebei Delin Machinery provides a full range of slurry pumps for various pumps in China, including the DM series mud pump (R). We are one of the leading manufacturers and suppliers in this field. The diameter of these mud pumps DM series (R) is 25-650mm. Our slurry pumps of horizontal design are exported mundialmente.

Application

Mud pump DM series (R) of Delin is suitable for transporting abrasive slurry medium, low density metallurgy, mining, coal and energóa industries, etc. For example, the transport of sludge in mining, metallurgy, power plants, steel mill and chemical industries, etc.

Characteristics

1. mud pumps DM series (R) is designed with double revestimiento.

2. High efficiency, wear-resistant, stable performance and full interchangeability are main features of our series mud pump DM (R) .

3. The material of the liner and impeller adopts resistante metal wear rubber for our slurry pumps design horizontal.

4. The discharge area can be positioned in eight different positions in a range of 45 ° .

5. Similar to our other series of horizontal slurry pumps design, mud pump DM series (R) can be also installed in multi-stage design and tape or coupling driven directo.

6. The shaft seal can adopt seal gland seal or expeller seal mecánico.

7. This series mud pump DM (R) must rotate in the direction of clockwise for a final ride.

Selection BoxPatameter performativeSettings

| Kind | Maximum Allowable Power (kW) | Material | Water Performance Aclaradoo | Driving |

| Lining | Driving | Capacity (Q) | Head (H) | Speed (n) | Effect Max. | NPSH | Wildebeest. blade | Day. Impeller (mm) |

| (M³ / h) | (L / s) | (M) | (R / min) | (%) | (M) |

| 25X20DM-A | 7.5 | M | M | 2.34 ~ 10.8 | 0.65 ~ 3 | 6 ~ 37 | 1400 ~ 3000 | 30 | - | 4 | 152.4 |

| 75X50DM-B | fifteen | M | M | 16.2 ~ 76 | 4.5 ~ 20 | 9 ~ 44 | 1400 ~ 2800 | 55 | - | 4 | 190 |

| 100X75DM-C | 30 | M | M | 18 ~ 151 | 5 ~ 42 | 4 ~ 45 | 900 ~ 2400 | 57 | - | 4 | 229 |

| 150X100DM-D | 60 | M | M | 50 ~ 252 | 14 ~ 70 | 7 ~ 46 | 800 ~ 1800 | 60 | 2 ~ 3.5 | 4 | 305 |

| 200X150DM-E | 120 | M | M | 115 ~ 486 | 32 ~ 135 | 12 ~ 51.5 | 800 ~ 1500 | 65 | 2 ~ 6 | 4 | 381 |

| 250X200DM-E | 120 | M | M | 234 ~ 910 | 65 ~ 253 | 9.5 ~ 40 | 600 ~ 1100 | 64 | 3 ~ 6 | 4 | 457 |

| 300X250DM-S | 120 | M | M | 396 ~ 1425 | 110 ~ 396 | 8 ~ 30 | 500 ~ 800 | 77 | 2 ~ 10 | 5 | 550 |

| 350X300DM-S | 560 | M | M | 468 ~ 2538 | 130 ~ 705 | 8 ~ 60 | 400 ~ 950 | 79 | 2 ~ 10 | 5 | 653 |

| 400X350DM-S | 560 | M | M | 650 ~ 2800 | 180 ~ 780 | 10 ~ 59 | 400 ~ 840 | 81 | 3 ~ 10 | 5 | 735 |

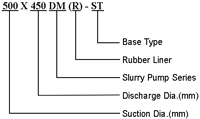

| 450X400DM (R) -ST | 560 | M | M | 720 ~ 3312 | 200 ~ 920 | 7 ~ 51 | 300 ~ 700 | 80 | 2 ~ 10 | 5 | 825 |

| M | M | 756 ~ 3312 | 210 ~ 920 | 7 ~ 37.5 | 6300 ~ 600 | 85 | 2 ~ 8 |

| 500X450DM (R) -ST | 560 | M | M | 1008 ~ 4356 | 280 ~ 1210 | 9 ~ 48 | 300 ~ 600 | 80 | 2 ~ 9 | 5 | 933 |

| RU | RU | 1080 ~ 4356 | 300 ~ 1210 | 9 ~ 40 | 300 ~ 550 | 87 | 3 ~ 10 |

| 650X550DM (R) -TU | 1200 | M | M | 1980 ~ 7920 | 560 ~ 2200 | 10 ~ 50 | 250 ~ 475 | 86 | 4 ~ 10 | 5 | 1213 |

| RU | RU | 1980 ~ 7920 | 700 ~ 2530 | 10 ~ 50 | 250 ~ 475 | 86 | 4 ~ 10 |

| Note: 1. M: material wear-resistant alloy, UK: rubber. 2. Recommended flow range: 50% ~ 110% Q'≤Q Q '(Q'≈ flow rate appropriate for the point of highest efficiency) 3. NPSH: recommended appropriate to point Q at the highest speed. |

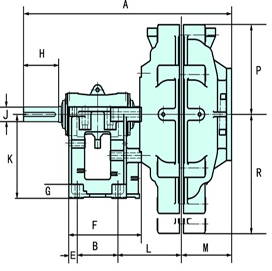

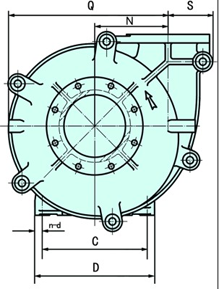

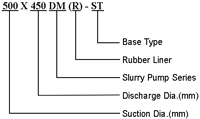

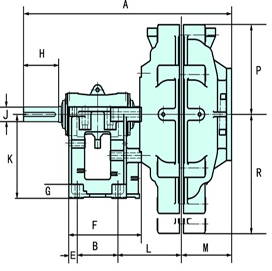

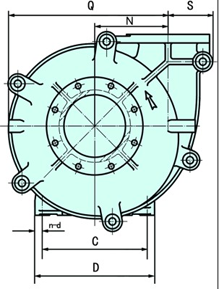

| Model | Outline Dimensions | | TO | B | C | D | AND | F | G | n-d | H | J | K | L | M | N | | 25X20DM-A | 461 | 159 | 241 | 286 | 25 | 210 | 28 | 4-Ф18 | 57 | 20 | 145 | 89 | 90 | 86 | | 75X50DM-B | 642 | 143 | 254 | 295 | 24 | 248 | 38 | 4-Ф14 | 80 | 28 | 197 | 191 | 136 | 114 | | 100X75DM-C | 813 | 175 | 358 | 406 | 32 | 311 | 48 | 4-Ф19 | 120 | 42 | 254 | 253 | 163 | 146 | | 150X100DM-D | 950 | 213 | 432 | 492 | 38 | 364 | 64 | 4-Ф22 | 163 | 65 | 330 | 280 | 187 | 190 | | 200X150DM-E | 1218 | 257 | 546 | 622 | 54 | 448 | 76 | 4-Ф29 | 220 | 80 | 457 | 376 | 237 | 248 | | 250X200DM-E | 1334 | 257 | 546 | 622 | 54 | 448 | 76 | 4-Ф29 | 220 | 80 | 457 | 413 | 306 | 292 | | 300X250DM-S | 1406 | 490 | 560 | 680 | 50 | 590 | 70 | 4-Ф28 | 216 | 85 | 350 | 322 | 324 | 438 | | 350X300DM-S | 1720 | 640 | 760 | 920 | 70 | 780 | 90 | 4-Ф35 | 280 | 120 | 450 | 415 | 300 | 475 | | 400X350DM-S | 1776 | 640 | 760 | 920 | 70 | 780 | 90 | 4-Ф35 | 280 | 120 | 650 | 425 | 340 | 530 | | 450X400DM (R) -ST | 1840 | 620 | 9 o'clock | 1150 | 80 | 780 | 125 | 4-Ф48 | 280 | 120 | 650 | 480 | 375 | 6 o'clock | | 500X450DM (R) -ST | 1875 | 620 | 9 o'clock | 1150 | 80 | 780 | 125 | 4-Ф48 | 280 | 120 | 650 | 5 o'clock | 400 | 660 | | 650X550DM (R) -TU | 2400 | 860 | 1200 | 1460 | 95 | 1050 | 150 | 4-Ф79 | 350 | 150 | 9 o'clock | 625 | 5 o'clock | 86 |

|

| Model | Size of the pump head | Dimension Input Flange | Dimension Output Flange | | S | Q | R | P | O.D | I.D. | C-C BET. Holes | Holes | O.D | I.D. | C-C BET. Holes | Holes | | 25X20DM-A | 144 | - | - | 128 | 114 | 25 | 83 | 4-Ф14 | 102 | 20 | 73 | 4-Ф14 | | 75X50DM-B | - | 155 | - | 163 | 184 | 75 | 146 | 4-Ф19 | 165 | 50 | 127 | 4-Ф19 | | 100X75DM-C | 102 | - | - | 204 | 229 | 100 | 191 | 4-Ф19 | 203 | 75 | 165 | 4-Ф19 | | 150X100DM-D | 118 | - | - | 262 | 305 | 150 | 260 | 4-Ф22 | 229 | 100 | 191 | 4-Ф22 | | 200X150DM-E | 155 | - | - | 324 | 368 | 200 | 324 | 4-Ф19 | 305 | 150 | 260 | 4-Ф19 | | 250X200DM-E | 199 | - | - | 401 | 445 | 250 | 394 | 8-Ф22 | 382 | 200 | 337 | 8-Ф22 | | 300X250DM-S | 257 | 476 | 603 | 470 | 552 | 305 | 495 | 8-Ф22 | 483 | 254 | 425 | 8-Ф22 | | 350X300DM-S | 165 | 599 | 634 | 570 | 560 | 350 | 5 o'clock | 12, Ф26 | 530 | 300 | 470 | 12, Ф26 | | 400X350DM-S | 295 | 643 | 691 | 620 | 640 | 400 | 580 | 12, Ф26 | 590 | 350 | 530 | 12, Ф26 | | 450X400DM (R) -ST | 343 | 747 | 809 | 740 | 720 | 450 | 650 | 12, Ф33 | 685 | 400 | 615 | 12, Ф33 | | 500X450DM (R) -ST | 375 | 814 | 872 | 800 | 770 | 5 o'clock | 700 | 12, Ф33 | 740 | 450 | 670 | 12, Ф33 | | 650X550DM (R) -TU | 453 | 1055 | 1142 | 975 | 975 | 650 | 880 | 12, Ф39 | 9 o'clock | 350 | 800 | 12, Ф39 |

|

Diameter: 25-650mm

Diameter: 25-650mm.jpg)