Parameter

Discharge Diameter: 25-450mm

Fluid rate: 7-5000m³

Head: 5-59m (Single Phase)

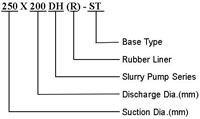

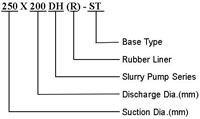

Model Implication

Description

As one of the largest manufacturers of centrifugal pump in China. We provide a complete range of pumping solutions. With double skin construction, horizontal slurry pumps series DH (R), is known for its high efficiency, wear resistant, stable performance and excellent interchangeability. The liner and the pump material motorcycle adopting metal and wear-resistant rubber. Downloading sector can be positioned in 8 different positions within a range of 45 °. In addition, sludge pumps horizontal series DH (R) can be upgraded to multi-stage, if needed to get up. And for the type of driving, they can be supplied with driving belt V or direct drive configuration. The shaft seal can be adopted to seal glands, seal or stamp of the ejector mechanism. The pump must rotate in the direction of clock hands for driving final.

DH series centrifugal pump (R) is single phase, rubber lining, double-coated, heavy-duty horizontal or sludge pumps for heavy-duty mining, ideal for various applications where long or large, fibrous solids can be handled.

Application

Pumps horizontal sludge series DH (R) are suitable for the supply of abrasive slurries, sludge high density metallurgy, mining, carpet, and energy industries, and so on, for example, bare mineral, medium concentrated waste , etc.

Selection BoxPatameter performative| Model | Efficiency Max. Allowed (kW) | Material | Clear Water Performance | Impeller |

| Lining | Driving | Flow rate (Q) | Head (H) | Speed (n) | Maximum Efficiency | NPSH | Impeller No. | Impeller Dia. |

| m³ / h | l / s | m | r / min. | % | m | | |

| 40X25DH (R) -B | fifteen | M | M | 12.6-26.8 | 3.5-8 | 6-68 | 1200-3800 | 40 | 2--4 | 5 | 152 |

| RU | RU | 10.8-25.2 | 3--7 | 7-52 | 1400-3400 | 35 | 2-4 | 3 | 152 |

| 40X25DHH-C | 30 | M | M | 16.2-34.2 | 4.5-9.5 | 25-92 | 1400-2200 | 20 | 2-5.5 | 5 | 330 |

| 50X40DH (R) -B | fifteen | M | M | 32.4-72 | 9--20 | 6-58 | 1200-3200 | 4. 5 | 3.5-8 | 5 | 184 |

| RU | RU | 25.2-54 | 7--15 | 5.5-41 | 1000-2600 | 50 | 2.5-5 | 5 | 178 |

| 70X50DH (R) -C | 30 | M | M | 39.6-86.4 | 11 to -24 | 12-64 | 1300-2700 | 55 | 4--6 | 5 | 214 |

| RU | RU | 36-75.6 | 10 to -21 | 13-46 | 1300-2300 | 60 | 2--4 | 5 | 213 |

| 70X50DHH-D | 60 | M | M | 68.4-136.8 | 19-38 | 25-87 | 850-1400 | 47 | 3-7.5 | 5 | 457 |

| 100X75DH (R) -C | 30 | M | M | 86.4-198 | 24-55 | 9-52 | 1000-2200 | 71 | 4--6 | 5 | 245 |

| RU | RU | 79.2-180 | 22-50 | 5-34.5 | 800-1800 | 59 | 3--5 | 5 | 245 |

| 100X75DHH-E | 120 | M | M | 126-252 | 35-70 | 12-97 | 600-1400 | 50 | 2--5 | 5 | 508 |

| 150X100DH (R) -D | 60 | M | M | 162-360 | 40-100 | 12-56 | 800-1550 | 65 | 5--8 | 5 | 365 |

| RU | RU | 144-324 | 40-90 | 12-45 | 800-1350 | 65 | 3--5 | 5 | 365 |

| 150X100DHH-S | 560 | M | M | 324-720 | 90-200 | 30-118 | 600-1000 | 64 | 3--8 | 5 | 711 |

| 200X150DH (R) -R | 300 | M | M | 360-828 | 100-230 | 10-61 | 500-1140 | 72 | 2 to -9 | 5 | 510 |

| RU | RU | 324-720 | 90-200 | 7-49 | 400-1000 | 65 | 5--10 | 5 | 510 |

| 250X200DH-E | 120 | M | M | 666-1440 | 185-400 | 14-60 | 600-1100 | 73 | 4--10 | 5 | 549 |

| 250X200DH (R-ST) | 560 | M | M | 612-1368 | 170-380 | 11-61 | 400-850 | 71 | 4--10 | 5 | 686 |

| RU | RU | 540-1188 | 150-330 | 12-50 | 400-750 | 75 | 4--12 | 5 | 686 |

| 300X250DH (R) -ST | 560 | M | M | 936-1980 | 260-550 | 7-68 | 300-800 | 82 | 6 | 5 | 762 |

| RU | RU | 720-1620 | 200-450 | 7-45 | 300-650 | 80 | 2.5-7.5 | 5 | 762 |

| 350X300DH (R) -ST | 560 | M | M | 1260-2722 | 350-770 | 13-63 | 300-600 | 77 | 3--10 | 5 | 965 |

| RU | RU | 1152-2520 | 320-700 | 13-44 | 300-500 | 79 | 3--8 | 5 | 965 |

| 400X350DH-TU | 1200 | M | M | 1368-3060 | 380-850 | 11-63 | 250-550 | 79 | 4--10 | 5 | 1067 |

| 500X400DH-TU | 1200 | M | M | 2520-5400 | 700-1500 | 13-57 | 200-400 | 85 | 5--10 | 5 | 1370 |

| Note: 1. M: material wear resistant alloy RU: Rubber 2. Scope of suggested capacity: 50% Q'≤Q'≤110% (Q'≈ appropriate for efficient capacity at the highest point) 3. NPSH: Appropriate Suggested to point Q at high speed. |

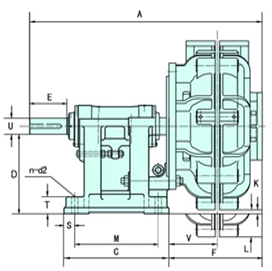

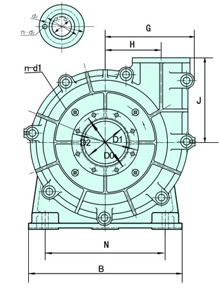

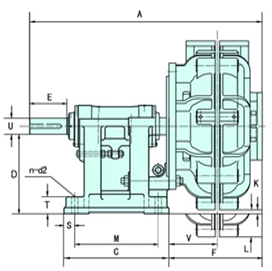

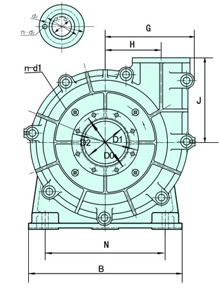

| Model | TO | B | C | D | OR | AND | F | G | H | J | K | L | M | N | V | T | S | n-d | | 40X25DH (R) -B | 583 | 295 | 248 | 197 | 28 | 79 | 206 | 181 | 98 | 171 | 46 | - | 143 | 254 | 181 | 38 | 24 | 4-Φ14 | | 40X25DHH-C | 759 | 406 | 311 | 254 | 42 | 121 | 306 | 270 | 194 | 254 | - | eleven | 175 | 356 | 252 | 48 | 32 | 4-θ19 | | 50X40DH (R) -B | 592 | 295 | 428 | 197 | 28 | 79 | 217 | 205 | 114 | 184 | 33 | - | 143 | 254 | 184 | 38 | 24 | 4-θ14 | | 70X50DH (R) -C | 768 | 406 | 311 | 254 | 42 | 121 | 281 | 238 | 138 | 210 | 71 | - | 175 | 356 | 233 | 48 | 32 | 4-θ19 | | 70X50DHH-D | 986 | 492 | 364 | 330 | 65 | 164 | 389 | 384 | 254 | 368 | - | 51 | 213 | 432 | 298 | 64 | 38 | 4-θ22 | | 100X75DH (R) -C | 843 | 406 | 311 | 254 | 42 | 121 | 354 | 292 | 149 | 262 | 24 | - | 185 | 356 | 270 | 48 | 32 | 4-θ19 | | 100X75DHH-E | 1240 | 622 | 448 | 457 | 80 | 222 | 492 | 492 | 330 | 432 | - | - | 257 | 546 | 381 | 76 | 54 | 4-θ29 | | 150X100DH (R) -D | 1021 | 492 | 364 | 330 | 65 | 164 | 421 | 406 | 229 | 338 | eleven | - | 213 | 432 | 318 | 64 | 38 | 4-θ22 | | 150X100DH (E) -E | 1178 | 622 | 448 | 457 | 80 | 222 | 433 | 406 | 229 | 338 | 138 | - | 257 | 546 | 351 | 76 | 54 | 4-θ29 | | 150X100DHH-S | 1668 | 920 | 780 | 450 | 120 | 280 | 296 | 616 | 413 | 546 | - | 134 | 640 | 760 | 353 | 90 | 70 | 4-θ35 | | 200X150DH (R) -E | 1302 | 622 | 448 | 457 | 80 | 222 | 557 | 551 | 318 | 460 | - | 62 | 257 | 546 | 402 | 76 | 54 | 4-θ29 | | 200X150DH (R) -R | 1360 | 680 | 590 | 350 | 85 | 215 | - | 511 | 318 | 460 | - | 170 | 490 | 560 | 312 | 70 | 50 | 4-θ28 | | 200X150DHH-T | 2275 | 1150 | 1040 | 650 | 150 | 350 | 852 | 835 | 584 | 813 | - | 160 | 880 | 9 o'clock | 538 | 125 | 80 | 4-θ48 | | 250X200DH (R) -E | 1337 | 622 | 448 | 457 | 80 | 222 | 584 | 613 | 384 | 470 | - | 83 | 257 | 546 | 403 | 76 | 54 | 4-θ29 | | 250X200DH (R) -R | 1395 | 680 | 590 | 350 | 85 | 215 | - | 613 | 384 | 470 | - | 190 | 490 | 560 | 314 | 70 | 50 | 4-θ28 | | 250X200DH (R) -ST | 1748 | 1150 | 780 | 650 | 120 | 280 | 692 | 673 | 419 | 635 | 27 | - | 620 | 9 o'clock | 439 | 125 | 80 | 4-θ48 | | 300X250DH (R) -ST | 1816 | 1150 | 780 | 650 | 120 | 280 | 762 | 775 | 464 | 674 | - | 65 | 620 | 9 o'clock | 461 | 125 | 80 | 4-θ48 | | 350X300DH (R) -ST | 1873 | 1150 | 780 | 650 | 120 | 280 | 812 | 937 | 629 | 832 | - | 224 | 620 | 9 o'clock | 486 | 125 | 80 | 4-θ48 | | 400X350DH-ST | 2320 | 1460 | 1050 | 9 o'clock | 150 | 350 | 953 | 1048 | 660 | 889 | - | 84 | 860 | 1200 | 597 | 150 | 95 | 4-θ79 | | 500X400DH-TU | 2475 | 1460 | 1050 | 9 o'clock | 150 | 350 | 1100 | 1420 | 940 | 1230 | - | 420 | 860 | 1200 | 615 | 150 | 95 | 4-θ79 |

|

| | | | | | | | | | | | | | | | | | |